Content Menu

● Introduction

● Raw Material Selection and Preparation

● Initial Processing and Leaf Treatment

● Extraction Process

● Concentration and Purification

● Quality Control and Standardization

● Final Processing and Packaging

● Conclusion

● Frequently Asked Questions

Introduction

Green tea extract has emerged as one of the most significant natural supplements in the modern health and wellness industry. This concentrated form of green tea has garnered substantial attention due to its rich composition of bioactive compounds, particularly catechins and their most prominent representative, epigallocatechin gallate (EGCG). The production of green tea extract involves a sophisticated series of processes that transform fresh Camellia sinensis leaves into a potent extract containing concentrated beneficial compounds. This comprehensive analysis explores the intricate steps involved in green tea extract production, from leaf selection to final processing, while examining the various factors that influence the quality and efficacy of the final product.

Raw Material Selection and Preparation

The journey of green tea extract production begins with the careful selection of tea leaves. The quality of the final extract is heavily dependent on the initial raw material selection process. Tea leaves are harvested from Camellia sinensis plants, with particular attention paid to the harvesting time and conditions. The most prized leaves are typically the youngest, freshest leaves and buds, as these contain the highest concentrations of beneficial compounds. The harvesting process is often conducted during early morning hours when the leaves contain optimal levels of active compounds. After collection, the leaves undergo immediate processing to prevent oxidation, which could otherwise alter their chemical composition and reduce the concentration of desired compounds.

Initial Processing and Leaf Treatment

The initial processing phase is crucial in preserving the beneficial compounds within the tea leaves. This stage involves several critical steps that must be executed with precision to maintain the integrity of the active ingredients. The first step is withering, where fresh leaves are spread out to reduce moisture content under controlled conditions. This is followed by heat treatment or "fixing," which involves exposing the leaves to high temperatures briefly to deactivate the enzymes responsible for oxidation. This process is essential in maintaining the characteristic properties of green tea and its extract, as it prevents the conversion of catechins into theaflavins and thearubigins, compounds more commonly found in black tea.

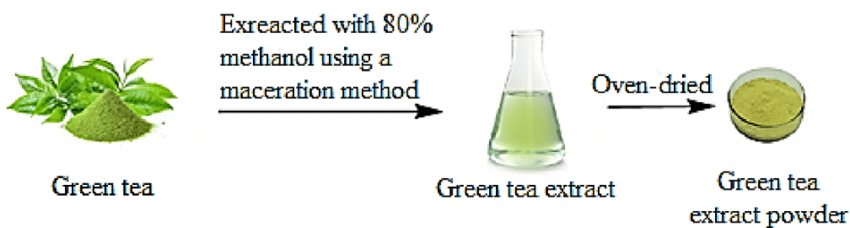

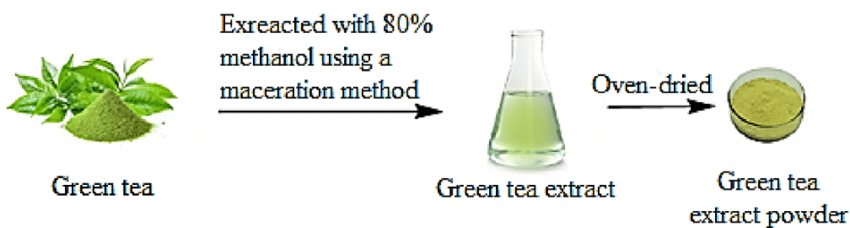

Extraction Process

The extraction process represents the core of green tea extract production and involves several sophisticated steps designed to isolate and concentrate the beneficial compounds. The process typically begins with the preparation of the processed tea leaves, which are ground into a fine powder to increase surface area and improve extraction efficiency. The extraction itself can be conducted using various methods, including:

1. Solvent Extraction: This traditional method uses water or organic solvents to extract the active compounds. The choice of solvent significantly impacts the final composition of the extract, with different solvents preferentially extracting different compounds.

2. Supercritical Fluid Extraction: A more advanced method utilizing supercritical carbon dioxide, which offers superior selectivity and leaves no solvent residues in the final product.

3. Ultrasound-Assisted Extraction: This modern technique employs ultrasonic waves to enhance the extraction efficiency and reduce processing time while maintaining the integrity of the active compounds.

Concentration and Purification

Following the initial extraction, the resulting solution undergoes several concentration and purification steps to achieve the desired potency and purity levels. This phase involves multiple stages:

1. Filtration: The extract undergoes various filtration processes to remove solid particles and impurities.

2. Concentration: The filtered solution is concentrated through evaporation under controlled conditions to reduce water content while preserving the active compounds.

3. Standardization: The extract is analyzed and adjusted to ensure consistent levels of key compounds, particularly EGCG and other catechins.

Quality Control and Standardization

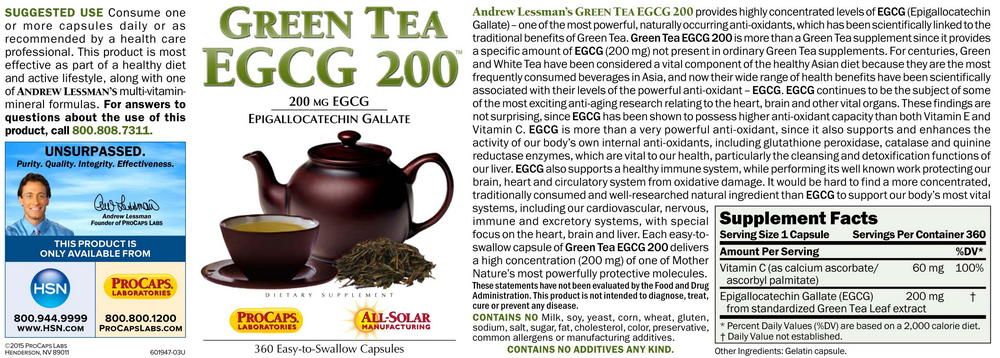

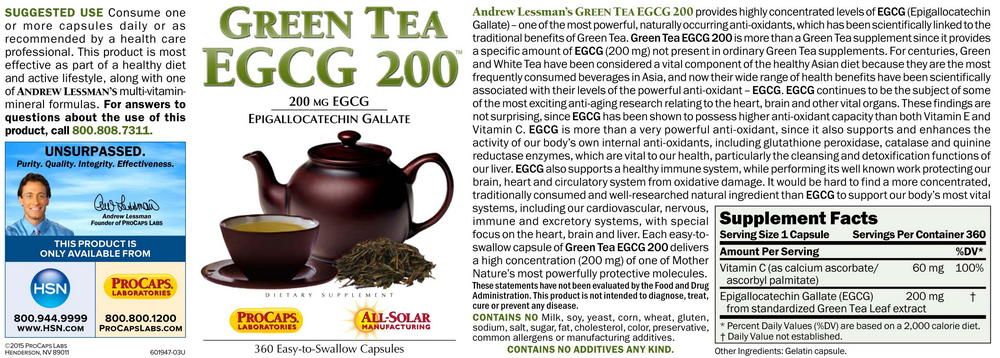

Quality control represents a critical aspect of green tea extract production, ensuring that the final product meets established standards for purity, potency, and safety. This phase involves comprehensive testing and analysis:

1. Chemical Analysis: Determination of catechin content, particularly EGCG levels

2. Contamination Testing: Screening for heavy metals, pesticides, and microbiological contaminants

3. Stability Testing: Evaluation of the extract's stability under various storage conditions

4. Standardization Procedures: Adjustment of the extract to meet specified concentrations of active compounds

Final Processing and Packaging

The final processing stage transforms the concentrated extract into various forms suitable for commercial use. This may include:

1. Spray-drying to create a powder form

2. Encapsulation for supplement production

3. Incorporation into liquid formulations

4. Preparation of standardized extracts for research purposes

Conclusion

The production of green tea extract is a complex process that requires careful attention to detail at every stage, from initial leaf selection to final processing. The quality of the final product depends on numerous factors, including raw material quality, processing methods, and quality control measures. Understanding these processes is crucial for manufacturers, researchers, and consumers alike, as it impacts the efficacy and safety of the final product.

Frequently Asked Questions

Q: What is the optimal temperature for green tea extraction?

A: The optimal temperature typically ranges between 60-70°C, as this range allows for efficient extraction while preserving the integrity of heat-sensitive compounds.

Q: How does the extraction method affect the final product quality?

A: Different extraction methods can significantly impact the concentration and composition of active compounds in the final extract, with modern methods like supercritical fluid extraction offering superior selectivity and purity.

Q: What is the significance of standardization in green tea extract production?

A: Standardization ensures consistent levels of active compounds, particularly EGCG, making the product reliable for both research and commercial applications.

Q: How long does the entire extraction process typically take?

A: The complete process from fresh leaves to final extract can take anywhere from several days to weeks, depending on the specific methods and quality control procedures employed.

Q: What are the key factors that influence the quality of green tea extract?

A: Key factors include the quality of raw materials, harvesting conditions, processing methods, extraction techniques, and quality control measures implemented throughout the production process.